The hype around machine learning (ML) is reaching a fever pitch in technology circles, but one supply chain management vendor says it’s time to cut through the hype and take a more strategic, prioritized approach to machine learning.

The hype around machine learning (ML) is reaching a fever pitch in technology circles, but one supply chain management vendor says it’s time to cut through the hype and take a more strategic, prioritized approach to machine learning.

Kinaxis, based in Ottawa, Canada, is using a framework that lets executives see things from new viewpoints, assimilate complex concepts, and manage real-world problems and opportunities. The framework helps companies apply the right ML tools to solve the right supply chain problems, said Trevor Miles, VP of thought leadership for Kinaxis.

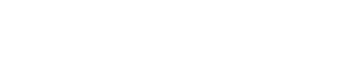

Cynefin Framework

“The key to how we think about the supply chain and planning in general is something I’ve discovered called the Cynefin Framework, because it breaks things down very nicely into four quadrants and then a center,” Miles said.

Cynefin (pronounced KUN-iv-in) is a Welsh word meaning habitat or haunt. The quadrants are “simple” (or “obvious”), “complicated,” “complex,” and “chaotic.” “With the simple stuff, you’ve seen it before,” he said. “You know how to react, so all you need to do is actually sense, categorize, and respond.”

Executives may be lulled into a false sense of security in the simple zone, with supply chain problems and solutions they understand. But problems may be incorrectly classified within a simple context, because they have been oversimplified.

“What people are really beginning to apply robotic process automation to is the so-called simple stuff,” Miles said. For instance, “customers changed their minds and want to change an order lead time by one day. They want to change the quantity by 10 percent—these types of things. You have standard practices, and you go through them.”

A company focused only on the simple zone may not survive something like Hurricane Harvey, which walloped Houston. Their supply chain processes and systems can’t handle more complex problems.

More Analysis Needed

Complicated contexts, on the other hand, may contain many right answers, though not everyone can see them. While supply chain managers in the simple quadrant must sense, categorize, and respond to a situation, those in the complicated zone must sense, analyze, and respond.

Residing in the complex zone are scenarios such as preparing your supply chain to survive a hurricane like Harvey, about which you have some data and knowledge of seasonal weather patterns. You don’t have all the facts, but you’re prepared. In this quadrant, “you have some standard approaches, but you don’t know where the hurricane is going to head, and you don’t know how hard it’s going to hit.”

The point is that supply chain managers need to analyze and prioritize potential problems, and think strategically about them, Miles said.

“The key thing here is, if you think everything is simple, you’re just going down the wrong route. You’re on a road to disaster. Because you’re going to be caught up by other events, and you’re not going be able to respond to them.”

Companies should avoid the middle of the Cynefin Framework, which is a blind spot labeled as “disorder,” Miles said.

“The middle is actually the uninformed little quadrant. That means you’re using the wrong process to satisfy the wrong problem. You might think that you’ve got simple processes, and standard processes, but now you’ve got a tsunami. And you’re trying to solve the tsunami in the same way as you would solve a small increase in demand. It isn’t going to happen.”

Treating the Supply Chain Like a Machine

Kinaxis has taken this approach one step further and has asked, how can we use the same framework for AI and ML? Kinaxis first focuses on all of the design parameters that go into how a supply chain operates.

“The design parameters are lead times, yields, all of these types of things. So essentially we are treating the supply chain like a machine. And we’re saying, what we need to do is to provide maintenance for that machine. We need to monitor vibrations and temperatures and pressures, and the moment we sense that its vibrations are slightly different, we need to tell somebody. Because that’s likely going to lead to a bigger problem somewhere.

“We’re ingesting all of this information about how the supply chain is performing historically. And we analyze it, looking for trends and patterns so that we can then raise that up to a human being to say, ‘something needs to be attended to.’ In many cases, we expect over time that people are going put this on auto pilot. But, initially, while this is all very new, people are probably going to want to still be the ones to push a button and to fix things.”

To illustrate this approach, Miles told the story of a recent drive he took from Grenoble to Geneva. He ended up with more car than he was expecting.

“I got some honking great Mercedes Benz by accident from the rental agency, and I was driving along the road and thought, ‘man, this is terrible.’ This thing’s steering wheel is all imbalanced or the wheels keep on rattling. And it took me about 10 minutes to say ‘Ah, I’ve got some driver’s assistance going on.’”

At that point, he paid more attention to the dashboard and noticed there was an auto-drive option.

“So there I was, doing 100 miles an hour down a French highway in this car. It was slowing down, it was turning corners, it was accelerating—all without me touching the pedals.

“I can tell you my feet were two millimeters above the pedals and my hands were one millimeter above the steering wheel. It was doing all of this itself. So my point here is we anticipate that our customers are going to have exactly the same response. They are going to have their hands one millimeter from the steering wheel. They’re not going to trust it initially, but this is why we’re going to allow them to have progressive automation. They can set tolerances wide. And we think that the tolerances are going be decreased over time so they can do this.”

Looking to the Future

Kinaxis’ foray into machine learning is consistent with its focus on what it calls “concurrent planning” and the “self-healing supply chain.”

“Planning is, of course, important, we do provide planning tools, but really, if you look at the true things we focus on, it is plan, monitor, respond. Yes, you need to create your plan, but you need to keep your finger on the pulse, understand when your plan is going off-kilter, and respond very quickly to right the ship again. Make sure you get back into the ‘green zone,’ as it were. Because it is about monitoring the system and understanding when it will go off track, and then being able to pull it all back as quickly as possible.”

Whenever artificial intelligence or machine learning is mentioned, people often object that it means the loss of jobs. However, nothing could be farther from reality, Miles said. AI/ML will not replace planners, he argued, but it will make them more productive by taking over the routine tasks in the simple quadrant. This frees them up to focus on the more important issues in the complicated, complex, and chaotic zones.

For more on Supply Chain Management, see our report Supply Chain Management Adoption Trends and Customer Experience.

Image Credit: Wikimedia Commons