In the era of Industry 4.0, adopting AI has become crucial for the manufacturing sector to improve operational efficiency, streamline processes, and enhance employee experiences. Generative AI (Gen AI) offers solutions to the manufacturing industry’s underutilization of vast data repositories owing to disparate data sources and unintegrated business units. It serves to accelerate digital transformation, enabling manufacturers to unlock valuable insights and gain a competitive edge in the digital market.

Difference between traditional AI and generative AI in manufacturing

Unlike traditional AI, which analyzes or acts on existing data, generative AI is capable of creating new content across different formats, including text, images, and code, based on user needs and requirements. Furthermore, with large language models, industries can move beyond the prescriptive tasks usually assigned to AI models. Generative AI can be far more proactive in anticipating new scenarios that were previously difficult to envision. This empowers manufacturing enterprises with accelerated product development cycles, streamlined manufacturing schedules, predictive maintenance models, and optimized supply chain operations, facilitating more informed decision-making processes.

What are the industry challenges for manufacturers that generative AI can solve?

While confronted by an array of challenges—ranging from an aging workforce and supply chain disruptions to performance inefficiencies and evolving consumer demands—the manufacturing sector is also navigating the complexities of current geopolitical and economic uncertainties. To address these multifaceted issues, organizations are increasingly investing in cutting-edge technologies. Among these, generative AI offers a transformative approach to tackle some challenges. It can serve as a key enabler in expediting the digital transformation journey and facilitating the transition to smart manufacturing. Manufacturers can leverage generative AI to significantly enhance productivity, reduce operational expenditures, and refine quality control mechanisms, thereby attaining a robust competitive edge in a complex business landscape. Consequently, a key question that emerges is the readiness of manufacturing enterprises to allocate the necessary resources and budget to advance their smart manufacturing initiatives to an even higher level.

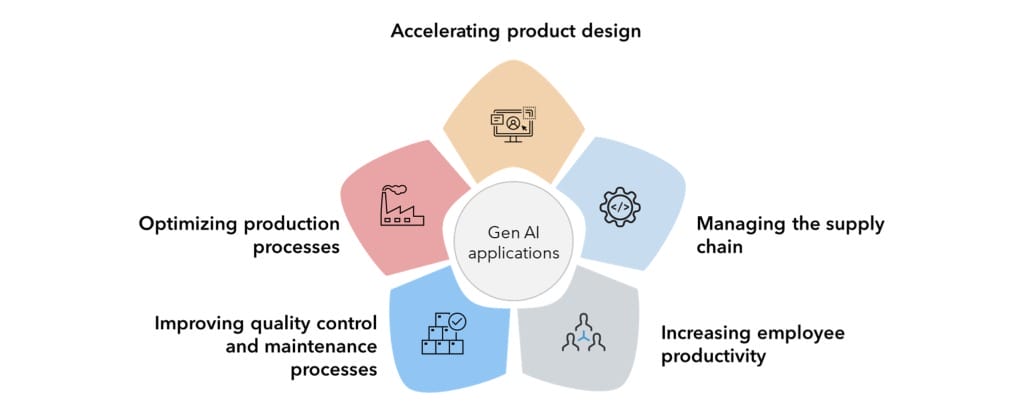

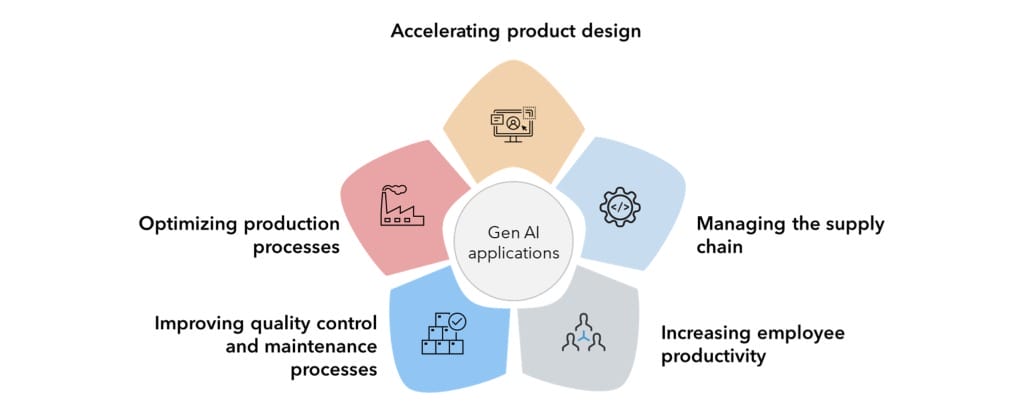

Top five areas where generative AI can help

In the first phase of generative AI adoption, enterprises are directing their efforts toward two main objectives: developing new revenue streams and improving internal efficiency. Within the manufacturing sector, the predominant application of generative AI is facilitating productivity enhancements. Manufacturers are strategically deploying new use cases across five broad categories to realize benefits from a productivity efficiency perspective:

-

- Accelerating product design – Design professionals in the manufacturing industry must carefully factor in parameters such as regulations, customer preferences, safety imperatives, and operational optimizations while developing new and pragmatic designs. In this context, the adoption of generative design is redefining the engineering process in new ways. Generative design can optimize a product design through parameters such as weight, durability, production costs, aesthetics, and others by specifying the required attributes. While the human touch is essential in developing creative and complex models, generative AI algorithms can provide initial foundational design drafts, which designers can use to channel their creativity into new additions. For example, Toyota utilizes a generative AI tool within its Toyota Research Institute to accelerate the design process for electric vehicles. The tool transforms text prompts into images, helping its employees create initial prototype sketches while accounting for engineering constraints such as aerodynamics and cabin size. Similarly, the toymaker Mattel has deployed the generative AI image creator tool, DALL-E, to enable its designers to explore new design options around parameters such as color and body shapes for its new Hot Wheels toy cars.

- Optimizing production processes – Manufacturers often deal with inefficiencies and bottlenecks in their production that require manual intervention. Generative AI tools can autonomously monitor the production process and address gaps to increase shop floor productivity. For instance, Swedish electrical manufacturer ABB partnered with Microsoft to integrate generative AI via Azure OpenAI service into its Genix Industrial Analytics and AI suite. This application empowers executives and shop floor engineers to make intuitive decisions, potentially extending asset lifespan by 20% and reducing unplanned downtime by 60% through access to real-time data insights. Large language models are also being fed live unstructured data to investigate bottlenecks and ensure optimal asset health. As a case in point, SparkCognition, an AI software provider, has developed a generative AI platform that can gather unprocessed data from sensors, convert them into comprehensible formats—such as text, images, and audio—and generate insights for manufacturers to act upon.

- Improving quality control and maintenance processes – Traditionally, manufacturers have widely used AI, specifically computer vision algorithms, for quality and defect inspection by enabling machines to learn and interpret visual data through images and videos. However, generative AI has the potential to enhance the quality control process by moving from a reactive to a proactive methodology and accelerating collaboration across business functions. For instance, in April 2023, Siemens launched the Teamcenter app for Microsoft Teams, which service engineers can use to log quality concerns on mobile devices. This involves translating natural speech to automatically create a summarized report and routing it to the appropriate technical or manufacturing expert within the Teamcenter app. Manufacturers are also implementing generative AI to simplify maintenance processes. For example, U.S. Steel has implemented MineMind™, an AI application developed in collaboration with GCP, at its Minnesota iron ore mines. Its goal is to increase the productivity of maintenance workers by using the Gen AI tool, which can provide optimized and summarized instructions in the form of SOPs, diagrams, and tools to use. Workers can ask the tool for instructions, and it will generate answers that are easy to follow and efficient.

- Managing the supply chain – Over the past few years, manufacturers have faced much supply chain backlash, so they are now keen on leveraging digital technologies to handle unexpected disruptions. Generative AI can be a powerful tool for such enterprises as it can work on massive data stacks, automate critical decision-making processes, and optimize parameters responsible for disruptions. For instance, FourKites, a supply chain intelligence platform provider, launched a generative AI platform, Fin AI, that can automatically diagnose supply chain issues, predict the impact of events on the shipping network, and help manufacturers make proactive decisions. Similarly, Inspectorio, a cloud-based supply chain solution provider, has launched an Inspectorio corrective and preventive actions recommender integrating Gen AI capabilities. This tool aims to improve quality control processes by identifying root causes of product defects and proposing personalized recommendations by analyzing historical data and discovering trends and patterns in the supply chain.

- Increasing employee productivity – Manufacturers are increasingly integrating generative AI tools to reap the benefits of improved employee productivity. Employees can leverage these tools to better perform repetitive tasks and conduct more efficient research. In February 2023, Panasonic launched ConnectAI, built with Microsoft Azure OpenAI Service, to enable its employees to create templates, write code, draft documents, and answer questions. Similarly, Cereal Partners Worldwide, a joint venture between Nestlé and General Mills, utilizes AnswerRocket’s Max Assistant using OpenAI’s GPT-4 to improve business intelligence insights, enabling employees to act faster through data-based insights.

What are the implementation challenges with generative AI?

While the advantages of adopting generative AI in business operations are apparent, it faces similar implementation challenges in manufacturing as observed in other industries:

-

- The outputs can often be unpredictable, which might raise questions about the reliability of the generated results. In April 2023, Nvidia introduced the NeMo Guardrails to develop safe and trustworthy LLM conversational systems.

- As Gen AI models are trained on public datasets, sharing sensitive information with public chatbots can lead to data privacy issues. For example, in April 2023, Samsung’s employees accidentally leaked confidential company information onto ChatGPT.

- The misuse of Gen AI for malicious activities, such as creating computer viruses or exploiting security vulnerabilities, is a growing concern. For instance, in July 2023, hackers used the WormGPT Gen AI tool to launch a series of phishing attacks.

- The processes of data collection and preparation can be quite time-consuming. Training the models also requires processors with high computational power. All of these translate into a high cost of development.

Thus, manufacturers must exercise due diligence when incorporating generative AI into their operational strategies.

Road ahead

With its intricate network of processes, stakeholders, and regulatory frameworks, the manufacturing industry presents unique considerations in the context of generative AI adoption. To reap the maximum benefits of generative AI in the future, manufacturers should invest in hiring the right digital talent and upskilling employees to increase their productivity levels. They will also have to envision a comprehensive organizational strategy to cater to the data requirements while addressing concerns such as biases, inaccuracies, intellectual property infringement, cybersecurity, and sustainability. The future of manufacturing belongs to enterprises that embrace AI-led transformation while remaining steadfast in their commitment to ethical, responsible, and sustainable practices.

By Anubhav Satapathy, Senior Analyst, and Parinita Singh, Research Leader, Avasant